Understanding Hydraulic Swivel Connectors: A Comprehensive Guide

Hydraulic connectors are pivotal in various industrial applications, enabling efficient and safe connections in hydraulic systems. Among these, the hydraulic swivel connector stands out for its unique capabilities and advantages.

What is a Hydraulic Swivel Connector?

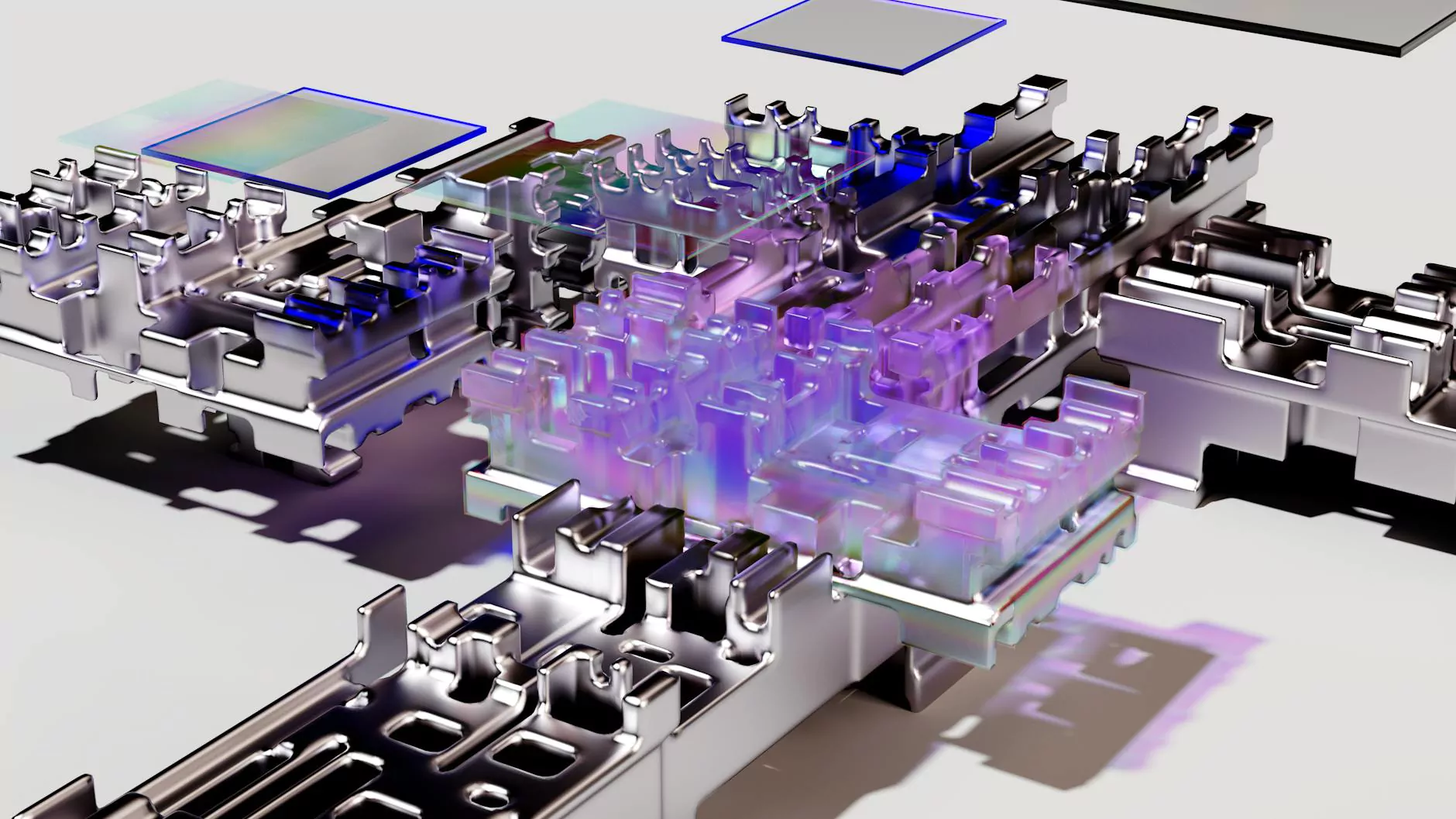

A hydraulic swivel connector is a specialized component that allows for the rotation of connected hydraulic lines without twisting or compromising the integrity of the hydraulic system. This feature is vital for applications involving movement or rotation, where traditional connectors would fail due to their inability to rotate freely.

Design and Construction of Hydraulic Swivel Connectors

The design of a hydraulic swivel connector incorporates various materials and technologies to ensure performance and durability. Typically, they are made from high-grade materials such as:

- Stainless Steel: Offers excellent corrosion resistance and strength.

- Brass: Provides good durability and is less costly.

- Aluminum: Lightweight and resistant to rust.

The construction often features a ball bearing or a pivoting mechanism allowing for effortless rotation while maintaining a sealed connection to prevent hydraulic fluid leaks.

Applications of Hydraulic Swivel Connectors

Hydraulic swivel connectors are utilized across various industries due to their essential role in fluid management systems. Some common applications include:

- Construction Equipment: Used in hydraulic hoses of excavators, cranes, and other heavy machinery.

- Marine Applications: Ideal for connecting hoses on boats where movement is prevalent.

- Aerospace: Ensuring secure connections in hydraulic systems where space is limited.

- Automotive Sector: Commonly found in hydraulic brakes and steering systems.

- Manufacturing and Robotics: Essential in machinery that requires fluid movement.

Benefits of Using Hydraulic Swivel Connectors

The integration of hydraulic swivel connectors into your hydraulic systems brings numerous advantages:

- Reduced Wear and Tear: By allowing movement without twisting, these connectors decrease the strain on the hoses and fittings.

- Improved Fluid Flow: They ensure a seamless flow of hydraulic fluid, enhancing the system's efficiency.

- Enhanced Safety: The design prevents leaks and potential hazards associated with hydraulic fluid spills.

- Versatility: Suitable for various applications and can be customized based on fitting needs.

Choosing the Right Hydraulic Swivel Connector

Selecting the appropriate hydraulic swivel connector for your needs requires careful consideration of several factors:

1. Pressure Rating

It's crucial to choose connectors that match your system's pressure requirements. Evaluate the maximum operating pressure to ensure safety and functionality.

2. Size and Compatibility

Measure the diameter and thread type of your existing fittings to find a compatible connector. Using the wrong size can compromise performance.

3. Environmental Considerations

Consider the operational environment. For example, if the connectors will be exposed to corrosive elements, select materials like stainless steel.

4. Manufacturer Reputation

Choose reputable manufacturers, such as those found on fitsch.cn, known for their high-quality hydraulic fittings, including hydraulic swivel connectors.

Maintenance of Hydraulic Swivel Connectors

Regular maintenance of hydraulic swivel connectors is essential for ensuring longevity and optimal performance. Here are some best practices:

- Routine Inspections: Regularly check for signs of wear, leaks, or damage.

- Cleanliness: Keep the connectors clean to prevent contamination of hydraulic fluid.

- Proper Storage: Store unused connectors in clean, dry environments to minimize corrosion.

- Use Appropriate Lubricants: Apply suitable lubricants to movable parts as recommended by the manufacturer.

The Future of Hydraulic Swivel Connectors

The demand for more advanced hydraulic swivel connectors is on the rise, driven by the increasing need for automation and efficiency in industrial applications. Innovations are expected to focus on:

- Enhanced Materials: Utilizing advanced composites and alloys to improve strength and reduce weight.

- Smart Technology: Integrating sensors to monitor performance in real-time.

- Sustainability: Developing eco-friendly materials and practices in manufacturing.

Conclusion

In conclusion, hydraulic swivel connectors play a pivotal role in ensuring smooth and efficient operations in various industrial sectors. By understanding their design, applications, and maintenance, businesses can enhance productivity and safety while minimizing downtime and operational costs. Prioritize quality by choosing reliable suppliers like fitsch.cn, and ensure your hydraulic systems operate at peak efficiency.

© 2023 Hydraulic Connectors Industry. All rights reserved.